Real-Time Engine Monitoring: Enhancing Performance and Reliability

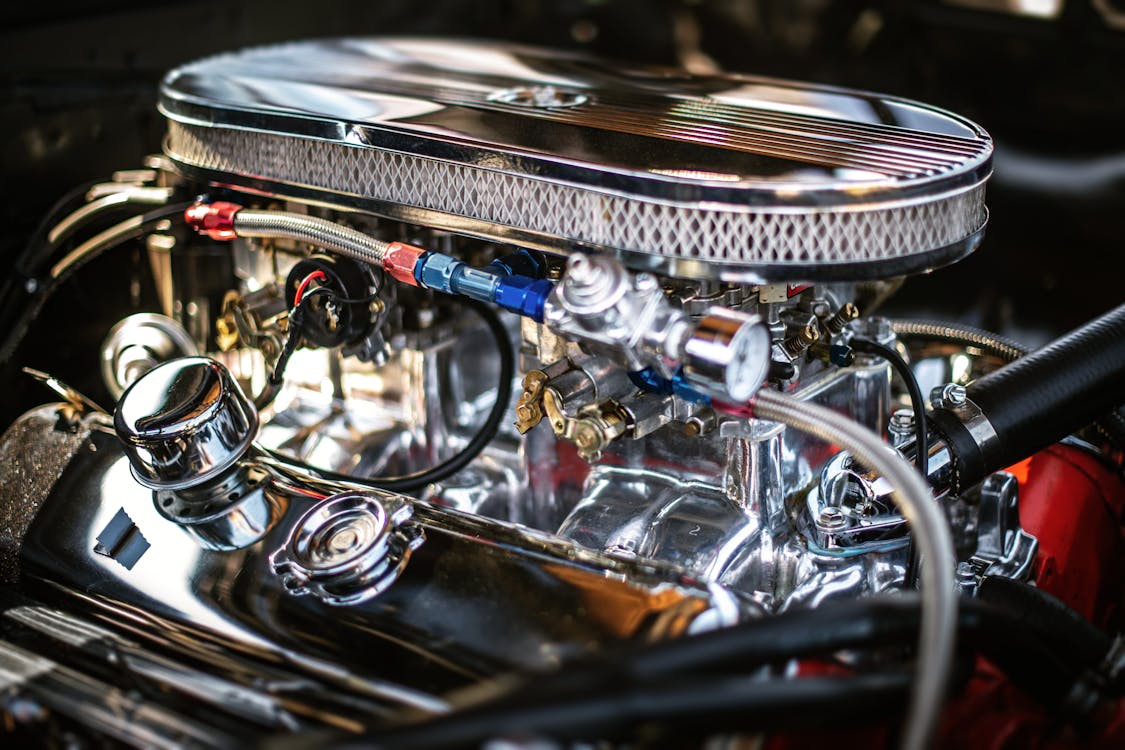

Real-time engine monitoring refers to the continuous and instantaneous observation of various parameters and conditions within an internal combustion engine as it operates. This monitoring process involves the use of sensors, data acquisition systems, and advanced software to collect, analyze, and display critical information in real time. The primary goal is to ensure optimal engine performance, efficiency, and reliability, while also identifying and addressing potential issues promptly.

|

| Real-Time Engine Monitoring: Enhancing Performance and Reliability |

Key Components of Real-Time Engine Monitoring:

Sensors:

- Temperature Sensors: Monitor the temperature of various engine components, such as coolant temperature sensors and exhaust gas temperature sensors.

- Pressure Sensors: Measure oil pressure, fuel pressure, and manifold pressure to ensure proper lubrication and fuel delivery.

- Speed and RPM Sensors: Track engine speed and revolutions per minute (RPM) for performance analysis.

- Vibration Sensors: Detect abnormal vibrations that may indicate mechanical issues or imbalances.

Data Acquisition Systems:

- Electronic Control Units (ECUs): Modern engines are equipped with ECUs that collect data from sensors and make real-time adjustments to optimize performance. They act as the brain of the engine management system.

- On-Board Diagnostics (OBD): OBD systems continuously monitor and report the health of various engine components, facilitating diagnostics and maintenance.

Advanced Software and Algorithms:

- Machine Learning and AI: Implementing machine learning algorithms and artificial intelligence allows for the analysis of complex data patterns, enabling predictive maintenance and early detection of potential issues.

- Diagnostic Software: Real-time engine monitoring often involves sophisticated diagnostic software that interprets sensor data, identifies anomalies, and provides insights into the overall health of the engine.

User Interfaces:

- Dashboards: Real-time engine data is often presented to the user through a dashboard, either on the vehicle's instrument cluster or on a separate display. This visual representation allows operators and technicians to quickly assess the engine's status.

- Alerts and Notifications: Immediate alerts and notifications are generated when the monitoring system detects abnormal conditions or potential failures, enabling quick response and preventive measures.

Parameters Monitored in Real-Time:

Temperature:

- Coolant Temperature: Monitors the temperature of the engine coolant to prevent overheating.

- Oil Temperature: Ensures that the engine oil is within the optimal temperature range for lubrication.

Pressure:

- Oil Pressure: Monitors the pressure of the engine oil to ensure proper lubrication.

- Fuel Pressure: Checks the pressure in the fuel system to guarantee adequate fuel delivery.

Speed and RPM:

- Engine Speed: Measures the speed of the engine's crankshaft.

- Revolutions Per Minute (RPM): Indicates the number of revolutions the engine crankshaft completes in one minute.

Vibration and Noise:

- Vibration Sensors: Detect abnormal vibrations that may indicate issues with engine components.

- Noise Level Monitoring: Some systems can analyze engine noise for anomalies, providing insights into potential problems.

Emission Parameters:

- Oxygen Sensors: Monitor the level of oxygen in the exhaust gases for efficient combustion and emission control.

- Exhaust Gas Temperature: Measures the temperature of the exhaust gases, aiding in emission control and turbocharger management.

Benefits of Real-Time Engine Monitoring:

- Early Issue Detection: Real-time monitoring allows for the early detection of abnormal conditions or potential failures, enabling timely intervention and preventive maintenance.

- Optimized Performance: Continuous monitoring enables the engine control system to make real-time adjustments to optimize fuel injection, ignition timing, and other parameters for maximum performance and efficiency.

- Reduced Downtime: Proactive identification of issues and prompt alerts help minimize downtime by allowing for timely maintenance and repairs.

- Improved Fuel Efficiency: Fine-tuning engine parameters based on real-time data contributes to improved fuel efficiency, reducing fuel consumption and operating costs.

- Enhanced Safety: Monitoring critical parameters in real time enhances safety by preventing catastrophic failures and ensuring the engine operates within safe limits.

Example Scenario: Real-Time Monitoring in a Vehicle Fleet:

Consider a scenario where a fleet of delivery vehicles is equipped with real-time engine monitoring systems. As the vehicles traverse various routes, the system continuously collects data on engine temperature, pressure, speed, and other parameters. If a vehicle's coolant temperature begins to rise abnormally, the monitoring system detects this change in real time and triggers an alert. The fleet manager receives immediate notification, allowing them to instruct the driver to pull over and investigate the issue before it escalates. This preventive action avoids potential engine damage and costly repairs, contributing to the overall efficiency and reliability of the vehicle fleet.

Challenges and Considerations:

- Sensor Accuracy: The accuracy and reliability of sensors are crucial for effective real-time engine monitoring. Regular calibration and maintenance are necessary to ensure precise data collection.

- Data Processing Speed: The speed at which the monitoring system processes data and generates alerts is critical for timely intervention. Delays in data processing may impact the system's effectiveness.

- Integration with Other Systems: Real-time engine monitoring systems need to seamlessly integrate with other vehicle systems, such as on-board diagnostics and maintenance management, to provide a comprehensive solution.

- Cybersecurity: As vehicles become more connected, ensuring the cybersecurity of real-time engine monitoring systems is essential to prevent unauthorized access and potential tampering.

Real-time engine monitoring represents a vital aspect of modern engine management, contributing to the efficiency, reliability, and safety of internal combustion engines in various applications, including automotive, aerospace, and industrial settings. Continuous advancements in sensor technology, data processing capabilities, and artificial intelligence are further enhancing the capabilities and potential of real-time engine monitoring systems